In the era of telecommunications and the hyperconnected world, a new concept has arisen that is already opening up new paths in the history of science and technology: industry 4.0.

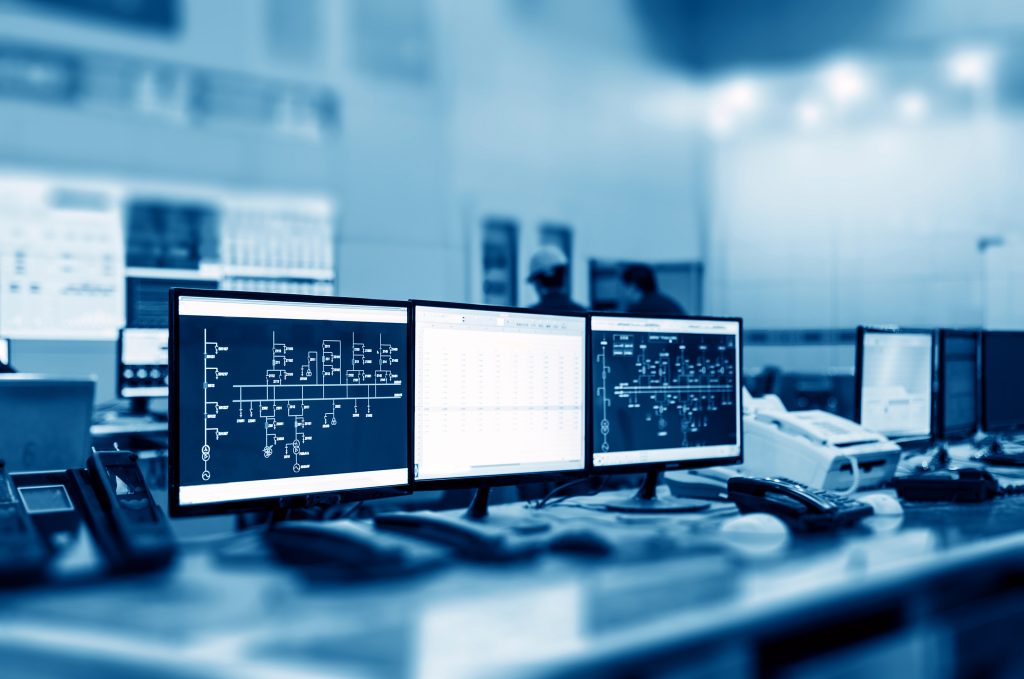

Smart factories and production centres, in which all of the systems are interconnected and can send, receive and analyse data are no longer a novelty.

The internet of things, artificial intelligence and cloud computing are transforming production processes, and communication between systems is becoming vital to industrial activities. Concepts such as predictive maintenance are becoming a key factor in any factory.

The benefits of this new production system are clear: cost and time savings, improved efficiency and energy consumption, fewer incidents and greater capacity to concentrate resources on new added-value activities.

Certainly, we could consider that this technological change will decrease people’s employability. This situation appears to be very new. However, if we look back, we can see how society has experienced transformations just as significant as this before. We could consider the first industrial revolution, when the rapid mechanization of the textile sector made it possible to increase output at the cost of initial job cuts.

What was the reaction to this process? There were those who blamed technology for taking jobs, and a movement (luddites) emerged to destroy and boycott the new machines and production systems; but the process was unstoppable. Most workers had to increase their knowledge and transform their skills to keep ahead of technology.

The question of jobs is the issue that causes most concerns in relation to industry 4.0. According to the Davos Forum, in the initial phase, a total of five million jobs would be lost worldwide. A high percentage of the most repetitive activities that contribute the least added value would disappear. However, as occurred in the nineteenth century, other possibilities and job profiles will emerge. Companies need workers with specific training in certain areas associated with each department or task, but they will also require knowledge of communication and programming. This will lead to new training pathways, and strengthen the concept of lifelong learning.

Furthermore, the use of machines and smart systems in mechanical activities will contribute to reducing accidents and incidents, so that employees can undertake less hazardous tasks that contribute more value to the entire production activity.

From the perspective of business innovation, we are still not capable of assessing the opportunities that are opening up in the field of advanced manufacturing, energy management, urban mobility or cybersecurity, for example.

There is a business demand to improve production processes that, in many cases, could be achieved by improving communication systems. A development by MCIA UPC that has been implemented in a metal company is a good example of this.

However, the real revolution is in taking advantage of full interconnection between all processes, to foster the creation of new products and services that meet some of the challenges that we face in the short-term in applications: the synchronized enterprise, improved production efficiency and energy distribution, waste optimisation, urban mobility and the use of robots in non-industrial activities (collaborative robots), to give just some examples.

In this endless race to contribute to improvements in industrial and business activity, through applied innovation, the challenges are as exciting as those faced by the companies and employees themselves: the advantages of technology must be take advantage of to continue to progress. We are faced by a new model that required more and better training, as well as increased collaboration with the production sector.

In this endless race to contribute to improvements in industrial and business activity, through applied innovation, the challenges are as exciting as those faced by the companies and employees themselves: the advantages of technology must be take advantage of to continue to progress. We are faced by a new model that required more and better training, as well as increased collaboration with the production sector.

It is a difficult challenge, but exciting. The history of technology is jumping forward a step, and we are there with it.

CIT UPC

Technology made real